Tel/Whatsapp : +8613770856222

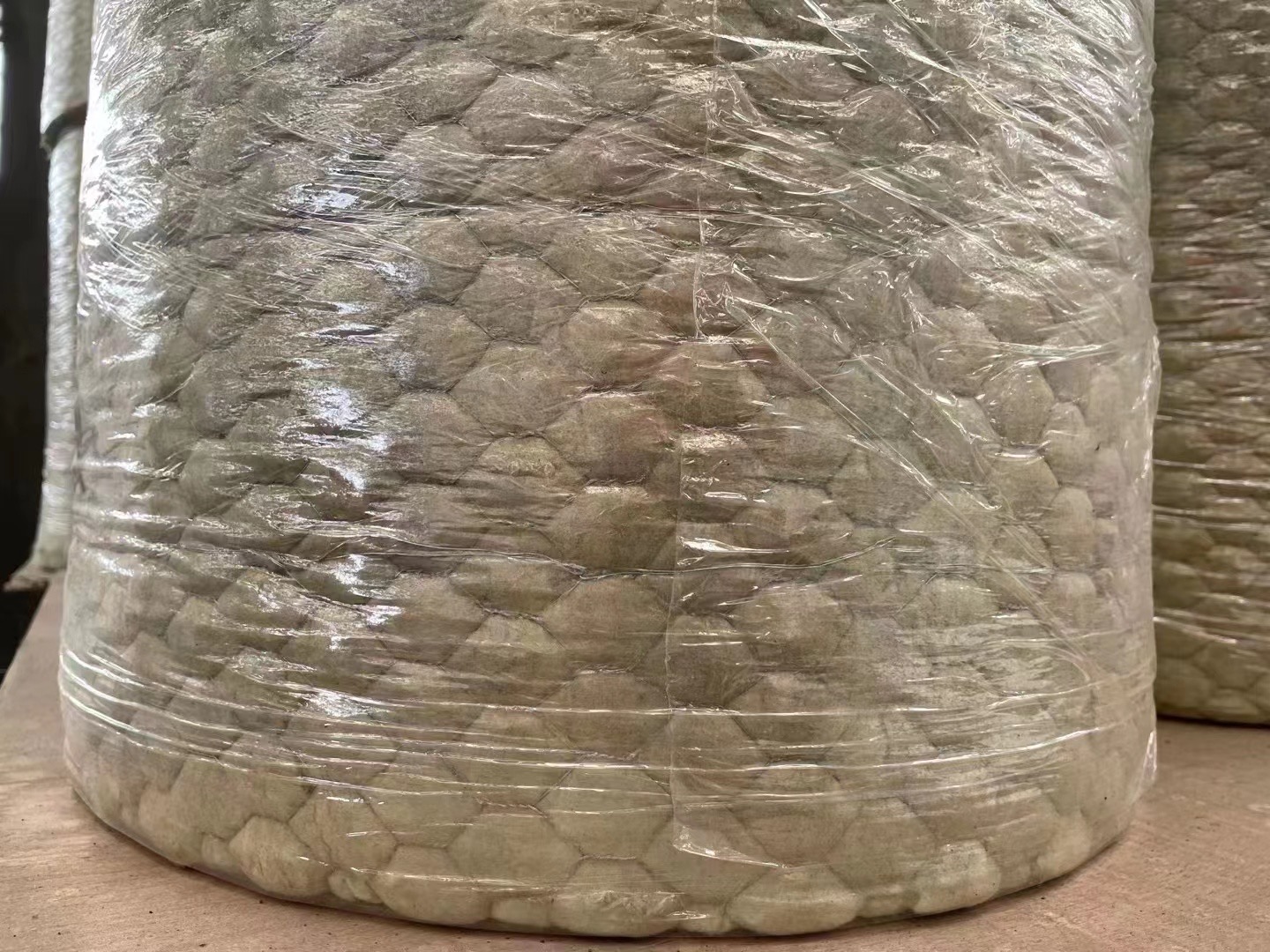

Zhongrunda Rock Wool Blanket Exported to UK

Time: August 21, 2022 Producer: Zhongrunda News Team

ZRD New Material's latest news: Nanjing Zhongrunda New Material's customer is a high-end rock wool factory in China. The galvanized barbed wire rock wool roll felt produced by our company is deeply loved by customers at home and abroad. Rock wool roll felt with galvanized wire mesh can be used in thermal insulation and fire protection projects for large tanks. Zhongrunda rock wool felt, in addition to providing customers with high-quality rock wool felt, Zhongrunda rock wool has conducted in-depth research and innovation on the roll diameter, fiber diameter, and flexibility of rock wool felt. In the case of the same 40-high cabinet, Zhongrunda rock wool roll felt can be installed about 20% more than other rock wool manufacturers, and it can ensure that the rigid technical indicators such as the thickness and density of the roll felt can be placed on the roll felt. After opening, it can still meet the requirements.

Zhongrunda pursues quality first.

On August 21, 2023, three 40-high cabinet roll felts of Zhongrunda were exported to the UK to provide high-quality rock wool roll felts for large-scale tank insulation construction parties in the UK. Zhongrunda rock wool roll felt has the CE certification of the European Union, which has quality assurance, and in terms of quantity: we can pack more boxes, which can help customers save a lot of shipping costs.

Knowledge expansion: tank insulation:

Can be divided into ground storage tanks, underground storage tanks, semi-underground storage tanks, offshore storage tanks, submarine storage tanks, etc. Storage tank The steel sealed container used to store liquid or gas is the steel storage tank. The steel storage tank project is an indispensable and important Infrastructure, our economic life is always inseparable from large and small steel storage tanks. The important role of steel storage tanks in the development of the national economy is irreplaceable. The electric heating reactor is widely used in chemical industry, food, paint, hot melt adhesive, silica gel, paint, medicine, petrochemical production, reaction, evaporation, synthesis, polymerization, saponification, sulfonation, chlorination, nitration and other process pressure Containers, such as reactors, reaction kettles, decomposition pots, polymerization kettles, etc. The reaction pot is mainly composed of four major parts: inner tank body, jacket, stirring device and support seat (with heat preservation structure can be used according to process requirements). Pressure vessels also make different regulations on the design, manufacturing process, and inspection items, contents and methods of each category of pressure vessels. The pressure vessel has implemented the safety and quality licensing system for imported commodities, and commodities that have not obtained the import safety and quality permit are not allowed to be imported. According to the classification of oil products, it can be divided into crude oil storage tanks, fuel oil storage tanks, lubricating oil storage tanks, edible oil storage tanks, fire fighting water tanks, etc.

.jpg)

Classified by use: can be divided into enterprise production, storage tanks, storage tanks, etc.

Divided by form: can be divided into vertical storage tanks, horizontal storage tanks, etc. According to the structure,

It can be divided into fixed roof storage tanks, floating roof storage tanks and spherical storage tanks.

According to the size: large tanks over 100 cubic meters, most of the vertical tanks, small tanks of 100 cubic meters, most of them are horizontal tanks. Tank standards: Commonly used tank standards: 1. Api 650 standard; api standard; 2. British Standard bs26543. Jisb8501;

Japanese standard

4. German standard DIN41195. Industry standard SYJ1016-82

German standard

6. Petrochemical Enterprise Industry Development Standard SH3046-92. The materials required for the storage tank engineering project are mainly divided into storage tank materials and auxiliary teaching facility construction materials. 4. The materials required for storage tank engineering management are divided into storage tank materials and auxiliary service facility equipment materials. 4. The materials required for storage tank engineering technology are divided into storage tank materials and auxiliary facility materials. 4. Materials required for storage tank engineering construction are divided into storage tank materials and auxiliary facility materials. Tank material we can pass according to tensile yield strength () or tensile standard working strength