Tel/Whatsapp : +8613770856222

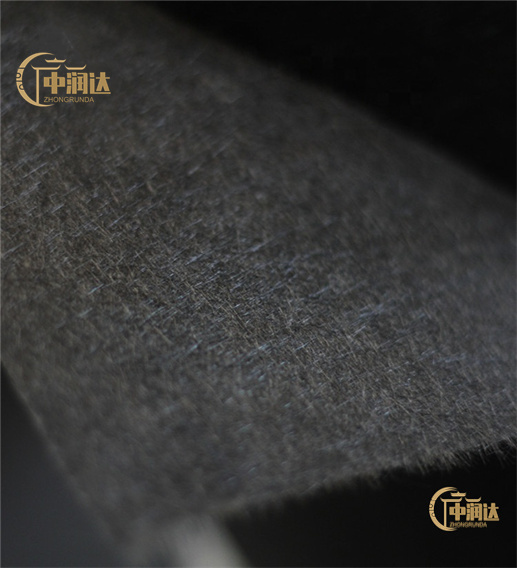

ZRD rock mineral wool products are made from natural rock such as basalt and dolomite.The natural rock are melted into melts in cupola at a high temperature about 1500°C.And the melts lava is then pour to high speed spinners through which the melts get into fibers.After that fibers are collected together to form the original wool mat through negative pressure resulted from suction. The original wool mats then pass through pendulum, crimping and pressing process, get into the curing oven through which the wool mats are cured and shape up to different kinds of products such as rock mineral wool board, rock mineral wool blanket, rock mineral wool strip and rock mineral wool pipe section etc with different usage.

China rock wool factory-china rock wool insulation

Energy consumption in residential and commercial buildings accounts for approximately 40% of society's total energy consumption and contributes to a similar proportion of global carbon dioxide emissions. The goal of the rock wool production enterprise is to become a facilitator of building and industrial energy-saving solutions.

Proper building energy design and insulation installation are critical to ensuring optimal energy efficiency and reducing greenhouse gas emissions. Rock wool is also suitable for extreme conditions as it maintains excellent insulating properties in both extremely low and extremely high temperatures.

Standard Specification

|

PRODUCT |

MB 40 |

MB 50 |

MB 60 |

MB 80 |

MB 100 |

MB 120 |

|

Density,kg/m3 |

40 |

50 |

60 |

80 |

100 |

120 |

|

Thickness,mm |

50~150 |

40~150 |

40~250 |

25~250 |

25~200 |

25~150 |

|

Length*widt,mm |

1200 x 600 |

|||||

Main Performance and Technical Indicators

|

Performance |

MB 40 |

MB 50 |

MB60 |

MB 80 |

MB100 |

MB120 |

Unit |

Standard |

|

Thermal conductivity ( 25 ℃) |

≤0. 037 |

W/(m •K) |

GB/T 10295 |

|||||

|

Combustion performance |

A1 |

--- |

GB 8624 |

|||||

|

Melting Temperature |

≥1000 |

℃ |

---- |

|||||

|

Surface Burning Properties |

Smoke Spread < 25 , Flame Spread < 25 |

--- |

ASTM E84 |

|||||

|

Acidity coefficient |

≥1.8 |

--- |

GB/T 5480 |

|||||

|

Hydrophobicity |

≥99 |

% |

GB/T 10299 |

|||||

|

Mass moisture absorption rate |

≤0.5 |

% |

GB/T 5480 |

|||||

|

Short-term water absorption (partial immersion, 24h) |

≤0.2 |

kg/m² |

GB/T 30805 |

|||||

|

Dimensional stability |

≤0.5 |

% |

GB/T 30806 |

|||||

|

Corrosive |

no corrosion |

--- |

ASTM C665 |

|||||

|

Formaldehyde emission |

≤0.5 |

mg/(kg•h) |

GB/T 32379 |

|||||

|

Noise Reduction Coefficient |

≥0.80 |

--- |

GB/T 18696 |

|||||

Application

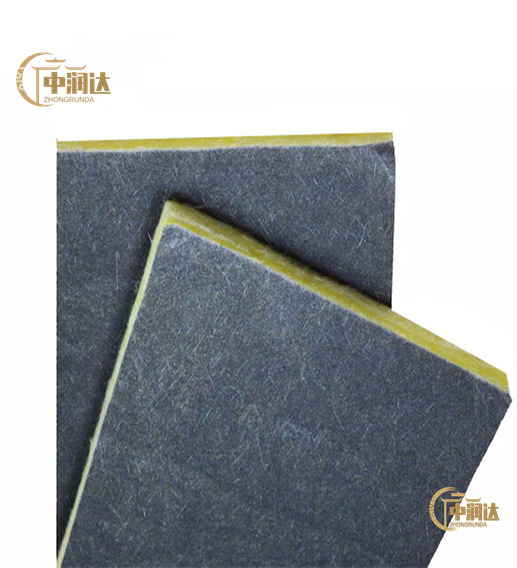

Zhongrunda Curtain Wall Rock Wool Board Curtain wall fireproof and thermal insulation rock wool board is specially designed for various curtain wall systems. It is a fireproof and thermal insulation product with the characteristics of higher fire resistance temperature, higher melting point, longer fire resistance and smaller high temperature linear shrinkage. . It is used for fire prevention and smoke barrier of the gap between curtain wall and floor or curtain wall and partition wall, and it can also be used for fireproof sealing of other building gaps, including gaps around pipes that pass through walls or floors. In order to enhance the smoke barrier ability, fireproof aluminum foil is generally pasted on the upper and lower surfaces of rock wool. It is mainly used for the fire separation of the window sill wall in the curtain wall system. Its superior thermal insulation performance can effectively reduce the heat transfer of this part. The surface can be pasted with decorative materials such as aluminum foil.