Tel/Whatsapp : +8613770856222

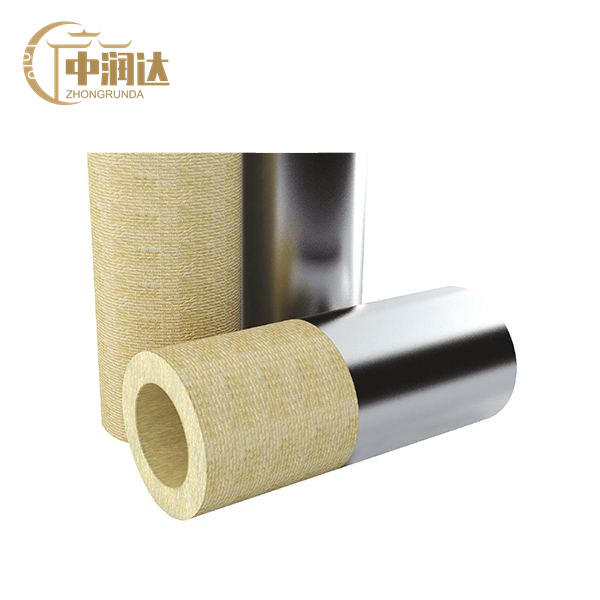

Material:Basalt Rock Wool Application:Thermal Insulation Thickness:25mm-100mm Density:64kg/m3 Feature:Eco-friendly Function:Heat Insulating Color:Yellow Main application: insulation and fireproof of huge projects like power plant, oil depot and petrochemical works

The rock wool fiber is rolled with a mold and formed by high temperature and solidification. For the convenience of installation, a unilateral slit is made along the axial direction of the shell, which is convenient for construction and can ensure that the shell is closely matched with the pipe that needs to be insulated. The outer surface of the shell can be polished according to customer requirements to ensure accurate and consistent insulation thickness. Hydrophobic and low-chlorine products can be produced according to requirements, and aluminum foil glass fiber cloth (ALGC) and other veneer materials can also be added to the surface.

Standard Specification

|

Tube Diameter |

Inside Diameter |

Thickness(mm) |

|||||||||||

|

mm |

(“) |

mm |

25 |

30 |

40 |

50 |

60 |

70 |

80 |

90 |

100 |

120 |

150 |

|

15 |

1/2 |

22 |

● |

● |

● |

● |

|

|

|

|

|

|

|

|

20 |

3/4 |

27 |

● |

● |

● |

● |

● |

● |

● |

|

|

|

|

|

25 |

1 |

34 |

● |

● |

● |

● |

● |

● |

● |

|

|

|

|

|

32 |

1- 1/4 |

43 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

|

|

40 |

1- 1/2 |

48 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

|

|

50 |

2 |

60 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

|

|

65 |

2- 1/2 |

76 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

|

|

80 |

3 |

89 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

|

|

90 |

3- 1/2 |

108 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

|

|

100 |

4 |

114 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

|

125 |

5 |

140 |

|

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

150 |

6 |

169 |

|

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

200 |

8 |

219 |

|

|

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

250 |

10 |

273 |

|

|

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

300 |

12 |

325 |

|

|

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

350 |

14 |

356 |

|

|

|

● |

● |

● |

● |

● |

● |

● |

● |

|

375 |

15 |

381 |

|

|

|

● |

● |

● |

● |

● |

● |

● |

● |

|

400 |

16 |

406 |

|

|

|

● |

● |

● |

● |

● |

● |

● |

● |

|

450 |

18 |

456 |

|

|

|

● |

● |

● |

● |

● |

● |

● |

● |

|

475 |

19 |

483 |

|

|

|

|

|

● |

● |

● |

● |

● |

● |

|

500 |

20 |

508 |

|

|

|

|

|

● |

● |

● |

● |

● |

● |

|

550 |

22 |

558 |

|

|

|

|

|

|

● |

● |

● |

● |

● |

|

600 |

24 |

610 |

|

|

|

|

|

|

● |

● |

● |

● |

● |

![]() Main Performance and Technical Indicators

Main Performance and Technical Indicators

|

Performance |

PS110 |

PS120 |

PS140 |

Unit |

Standard |

|

|

Density |

110 |

120 |

140 |

kg/m3 |

-- |

|

|

Thermal conductivity

|

5 0 C |

≤ 0.039 |

≤ 0.039 |

≤ 0.039 |

W/(m•K) |

GB/T 10295 ASTM C518 ASTM C177 |

|

1 0 0 C |

≤ 0.044 |

≤ 0.044 |

≤ 0.044 |

|||

|

1 5 0 C |

≤ 0.056 |

≤ 0.052 |

≤ 0.052 |

|||

|

2 0 0 C |

≤ 0.072 |

≤ 0.063 |

≤ 0.061 |

|||

|

2 5 0 C |

≤ 0.084 |

≤ 0.072 |

≤ 0.070 |

|||

|

3 0 0 C |

≤ 0.095 |

≤ 0.081 |

≤ 0.078 |

|||

|

Maximum operating temperature |

450 |

650 |

650 |

C |

ASTM C411 |

|

|

Veneer material: 80 |

||||||

|

Heat load shrinkage temperature |

400 |

600 |

600 |

C |

GB/T 11835 |

|

|

Linear shrinkage |

≤2 |

≤2 |

≤2 |

% |

ASTM C356 |

|

|

Volume moisture absorption* |

≤ 0.02 |

≤ 0.02 |

0.02 |

vol % |

ASTM C1104 M |

|

|

Hydrophobicity* |

99 |

99 |

99 |

% |

GB/T 10299 |

|

|

Chloride content** |

≤ 10 |

≤ 10 |

≤ 10 |

PPM |

ASTM C871 |

|

|

Combustion performance |

Nonflammability A1 Smoke degree <25 Flame Spread <25 |

-- |

GB 8624 ASTM E136 ASTM E84 |

|||

|

Organic content |

≤ 4.0 |

≤4.0 |

≤4.0 |

% |

GB11835 |

|

|

Environmental friendly |

Asbestos-free and free of CFSs, HCFCs and HFCs |

-- |

-- |

|||

|

Corrosive |

no corrosion |

-- |

ASTMC665 |

|||

* Hydrophobic grades only, ** Low chlorine grades for austenitic stainless steels only, per ASTM C795;

Other properties meet the requirements of GB/T 11835-2007 or ASTM C592.

Application

IPS series products are mainly used for thermal insulation of power plants or small-diameter cold and hot pipelines to protect personal safety, reduce or avoid condensation, and reduce noise.